Frequently Asked Questions

Please click on the links below to find answers to the most frequently asked questions about DiPS.

If there is a question you would like adding to this list please

e-mail

support@dips.co.uk

How to extend a DiPS Dongle in the Grace Period

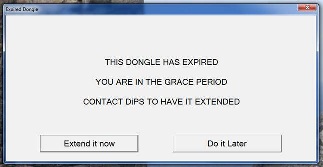

In an expiry period the following message

will appear –

Choosing Do It Later will continue

into the program ..

Choosing Extend It Now will then

show The Access Rights screen -

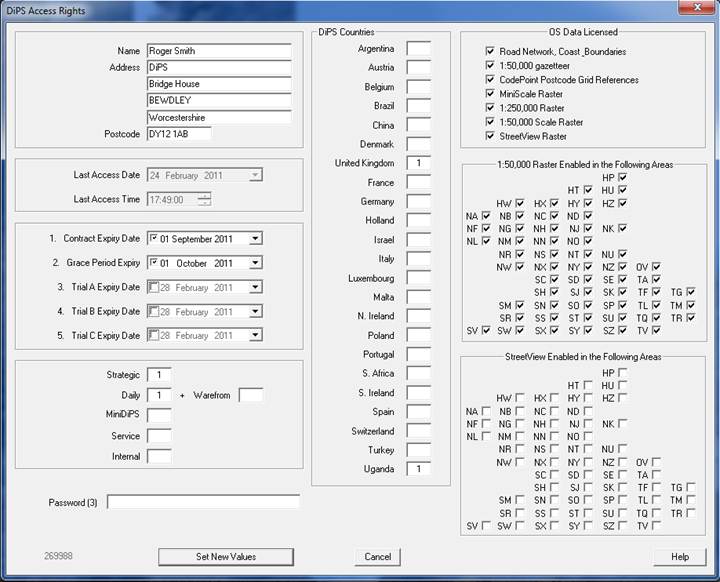

To set the dongles for the next period,

do the following:

Change the Contract Expiry Period to

be the date required (e.g. 1st September 2017)

Change the Grace Period Expiry to be

the date required

Enter the correct text as provided by DiPS

personnel in the Password (3) prompt.. (lower

case or capitals is not important)

Click on the Set New Values button

If successful, a message box with “Your

Dongle has been successfully Updated” will appear and the

program will then run as normal..

(Please note that it may take up to 30

seconds or so for this to appear)

Helpful Shortcut Keys

When looking through your routes in Egotrip mode:

Press F2 to go through routes with errors

Press F3 to quickly go to the next route

Press F4 to quickly go to the previous route

Press F9 to open the sysout file viewer

How DiPS Calculates Work Times

Work times are calculated based on Products or Units

or both; with a combination of other factors such as work

difficulty factors and extra time based on the Call, Vehicle and

Depot.

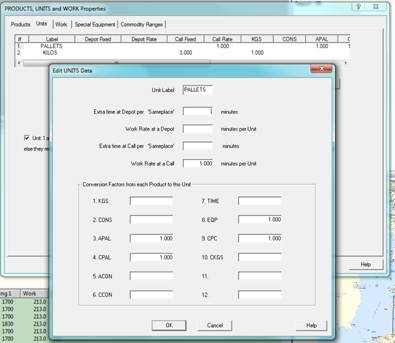

1. The main way is to set a Work rate based on the quantity of

units in an order ... Products loaded into Dips are converted

into a DiPS unit used for calculating the quantity that can fit

on the vehicles, etc. – e.g. converting products into Equivalent

Pallets.

Go to Edit -> products units and work – Click on the Units tab –

here you set the conversion factors for products into the unit

and can add a work rate per unit

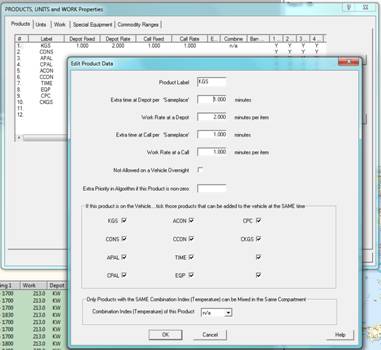

2. You can also set work rates based on the quantity of a

particular product

Edit -> Product units and work – Products tab

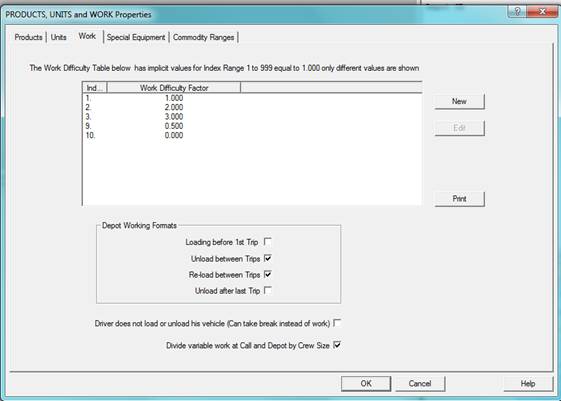

3. You can set work difficulty factors to use to factor the work

at certain calls or with specific vehicles – you set these up in

... Edit -> Product units and work – Work tab ... ready to

assign to calls later

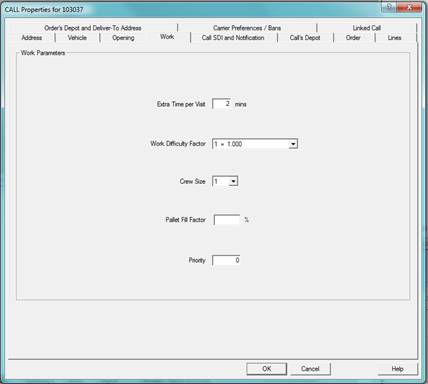

4. You can add extra time for specific calls as well as setting

difficulty factors for that call

Double click on a call to get the Call Properties -> Work tab

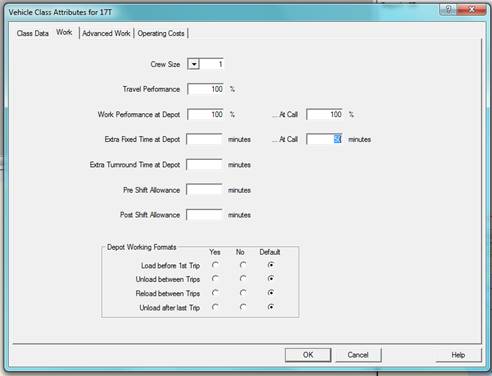

5. You can set up extra time and modify the work rate based

on the vehicle used

Edit -> vehicle classes -> double click a vehicle -> work tab

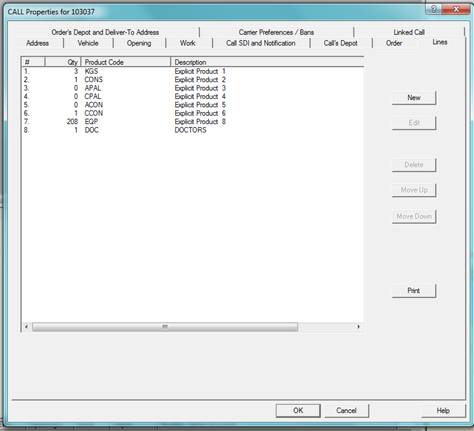

6. Finally the quantity of each product you have on an order

will drive the work time based on the parameters you have set

above

Call properties -> lines

Load Order Data from Spreadsheet

The File menu option Load Orders from

Excel Spreadsheet will process and input order information directly from an

Excel spreadsheet. This option is only available for specific report styles

defined in the File, Study, Settings dialog. The style ORDERXL can be used if

necessary as a short term measure. On running the option an initial dialog will

appear to select the spreadsheet to be loaded, followed by the page and options

dialog. Select the sheet or table to be used (default is always Sheet1) and then

tick the required options if necessary. Choose different delivery addresses if

orders have been defined that are to be delivered to another location rather

than that defined by the Call. Selecting rather of the Generate New options will

create system defined Order or Call numbers, meaning that the >*1 or >*2 columns

need not be defined or are ignored. Once data is loaded, click Apply to re-load

the model and. The preparation of the data must follow a few simple rules

1. Each new ORDER must occupy a

unique LINE in the spreadsheet.

2. The columns containing data to

be loaded must contain the correct labels as defined below in more detail.

Any column not containing this label will be ignored. In this way a selection of

columns may be used (e.g. columns A, C, D and F but not B or E).

3. The most left-hand '>...

labelled column must be the order ident. (NB This does not necessarily have to be

column 'A').

4. The data rows read from by DiPS

are defined by a pair of >> labels to the left of the

first and last rows of data. These labels cannot be placed in a column with

other valid DiPS data. The selected datarows should begin on line 2 – with the

headers being on line 1 of the spreadsheet.

>*1

Order Identifier (may be left justified text or a numeric value)

>*2

Call Identifier

(may be left justified text or a numeric value)

>*911

Order Tag Field

(up to 4 characters may be used)

>*9

Opening /Booked Time may be numeric or

time value (see below)

>*10

Closing Time

may be numeric or time value (see below)

>*11

Order Margin (value may be defined 2 to decimal places)

>*12

Order Linked Job (text field with the ident of an existing order to be routed next)

>*13

Skills Required (text field with Y or N flags for 1-32 skills e.g. YYYNNNY is skills 1,2,3,7

required)

>*912

Order Country

>*913

Special Delivery Instructions SDI Line 1 (80 characters text or up to 240 for

all 3 lines)

>*914

Special Delivery Instructions SDI Line 2 (up to 80 characters text for line 2

only)

>*915

Special Delivery Instructions SDI Line 3 (up to 80 characters text for line 3

only)

>*109

Due On Date (in format ddmmyyyy).

>*209

Due by Date (in format ddmmyyyy).

>*99 Order’s Pass Through Data

for display in user-defined columns

>D1

Force CALL to belong to the DEPOT named in this column

RESTRICTIONS Data

>R2

Call Opening Time 1 may be numeric or time format (hh:mm:ss)

>R3

Call Closing Time 1 may be numeric or time format (hh:mm:ss)

>R4

Call Opening Time 2 may be numeric or time format (hh:mm:ss)

>R5

Call Closing Time 2 may be numeric or time format (hh:mm:ss)

>R6

Day Restrictions

>R8

Extra Time per Visit

>R9

Work Difficulty Factor

>R10

Pallet Fill Factor

>R106

Nominated Days

>R107

Crew Size Required

>R108

Delivery Priority

>R7

Maximum Vehicle Class (MUST BE LEFT JUSTIFIED TEXT)

>R27 Maximum Vehicle Class

>R37

Side Loading Restrictions (L = left, R = right, F = front, T = tail or

appropriate combinations , e.g. L ,RT,LF)

>R47

Banned Vehicle Class 1 (doesn’t remove other banned classes)

>R57

Banned Vehicle Class 2 (doesn’t remove other banned classes)

>R67

Banned Vehicle Class 3 (doesn’t remove other banned classes)

>R77

Banned Vehicle Class 4 (doesn’t remove other banned classes)

>R11

Explicit Vehicle Class

ADDRESS Data

>A2

Grid Reference -

either a

Numeric EASTING (in which case >A3 is also required)

or an

Alphanumeric six digit

(1km accuracy) SU1234

or an

Alphanumeric eight digit (100m accuracy) SU120340

>A3

Numeric NORTHING (if >A2 is a numeric EASTING).

>A29

Numeric Easting for Ireland in UK projection

>A39

Numeric Northing for Ireland in UK projection

>A4

Name or Address Line 1

>A5

Address Line 2

>A6

Address Line 3

>A7

Postcode (automatically converts to Grid Reference)

>A8

Address Line 4

>A9

Address Line 5

>A11

Call Tag Field (up to 40 characters may be used)

>A12

Call Country (must be in a column before[ i.e. to the left of] any postcode

entry)

>A13

Special Delivery Instructions Line 1 (80 characters text or up to 240 for all 3

lines)

>A14

Special Delivery Instructions SDI Line 2 (up to 80 characters text for line 2

only)

>A15

Special Delivery Instructions SDI Line 3 (up to 80 characters text for line 3

only)

>A77

Call’s Postcode (only when used with Order Deliver-To Addresses option)

>A99 Call’s Pass Through Data for

display in user-defined columns

Totals for

Product Data or Commodity Range

^>AAA order quantity for product or commodity range

DiPS

recognises a Commodity Range header label because it must be centrally justified

using the carat symbol ^ . The next character must be the greater

than sign >. Finally the label contains the Commodity Range's name. As an example, for the

commodity range called FROZEN the demand quantity header would be

^>FROZEN. These commodity ranges or products must exist on the MASS file prior

to running the program.

Individual Values for Commodity Range Data

Using the ># label on the top of

a column allows multiple lines of quantity data to be loaded for each order. A

commodity range code is created using >#1 and then details for this commodity

loaded using subsequent ># columns. These commodity ranges do not have to

exist on the MASS file prior to running the program to load the orders. The last

row found for each commodity will be the quantity and conversions used. Rows

will not add together to produce a cumulative value for a single commodity.

>#1

Commodity Range Label (up to 20 characters text).

>#2

Commodity Description (up to 40 characters

text)

>#3

Primary Product Group No. (use numeric values of 1-12 to represent

products 1 to 12)

>#4

Primary Conversion factor (use numeric values up to 21,000 to

convert quantity into primary product)

>#5

Secondary Product Group No. (use numeric values of 1-12 to represent products 1 to 12)

>#6 Secondary Conversion

factor

(use numeric values up to 21,000 to convert quantity into second product)

>#7

Third Product Group No. (use numeric values of 1-12 to

represent products 1 to 12)

>#8

Third Conversion factor (use numeric values

up to 21,000 to convert quantity third product)

>#9

Quantity of this commodity (use numeric values to add a quantity of this

commodity)

Booked Times and Time Windows for

Orders and Calls

The >*9

flag may be used simply to define a single Booked Time for an Order using a

Numeric Value in 24hr format, such as 1000 for 10:00 hrs or 800 for 8:00 hrs.

For a Time Window, an 8 digit numeric value may be used giving from and to

times, i.e. 10001700 would give 10:00

to 17:00 hrs; or 8000900 for

08:00 to 09:00. The >*39 field can also be used to specify the Order

Closing Time window. Alternatively use the >R2 , >R3, >R4 and >R5 columns

to define opening and closing for the Call in separate columns

Other DiPS Headers to load from Spreadsheet

In terms of depots and calls the attributes correspond to header labels as follows :-

|

CALL Entity |

|

>C1 |

Call Identifier (up to 40

characters possible) |

|

>C2 |

Frequency (No. visits in Data

Collection Period) |

|

>C3 |

Cumulative Demand for PRODUCT 1

(negative if collections) |

|

>C4 |

Cumulative Demand for PRODUCT 2

(negative if collections) |

|

>C5 |

Cumulative Demand for PRODUCT 3

(negative if collections) |

|

>C6 |

Cumulative Demand for PRODUCT 4

(negative if collections) |

|

>C103 |

Cumulative Demand for PRODUCT 5

(negative if collections) |

|

>C104 |

Cumulative Demand for PRODUCT 6

(negative if collections) |

|

>C105 |

Cumulative Demand for PRODUCT 7

(negative if collections) |

|

>C106 |

Cumulative Demand for PRODUCT 8

(negative if collections) |

|

>C203 |

Cumulative Demand for PRODUCT 9

(negative if collections) |

|

>C204 |

Cumulative Demand for PRODUCT

10 (negative if collections) |

|

>C205 |

Cumulative Demand for PRODUCT

11 (negative if collections) |

|

>C206 |

Cumulative Demand for PRODUCT

12 (negative if collections) |

|

>C7 |

Total No. Drops in D.C.P. (not

required if same as >C2 ). |

|

>C8 |

Radius in Kms(only required if

>C7 is greater than >C2 i.e. pre-clustered) |

|

>C9 |

Enter

PAID

if Carriage Paid :

NO

to remove or set OFF (or Explicit Carrier Ident) |

|

>C10 |

Carrier does Collections (use

0=NO or

OFF, 1=YES

or SET ON) |

|

>C11 |

Call is never delivered by a

carrier (use 0=NO

or OFF, 1=YES

or SET ON) |

|

>C12 |

Call Margin value (up to 2

decimal places) |

|

>C15 |

Skills Required

text field with Y or N for 1-32 skills e.g. YYNNY

= skills 1,2,5) |

|

>C16 |

Next Linked Call Ident or use

NONE to

remove all linked data for this call |

|

>C40 |

Column header only will remove

all MASS file Call Products, Profiles or Multiple Data |

|

>D1 |

Force CALL to belong to this

DEPOT (>D1 must not be the 1st column) |

|

>C0 |

New Call Ident (changes the

existing ident to this new one, must follow in next

column to the right of >C1) |

|

ADDRESS Data for

Calls and Depots |

|

>A2 |

Grid Reference -

either a Numeric EASTING (in which case >A3 is

also required) or an Alphanumeric six digit (1km

accuracy) SU1234 or an Alphanumeric eight digit (100m

accuracy) SU120340 |

|

>A3 |

Numeric NORTHING (if >A2 is a

numeric EASTING). |

|

>A102 |

Numeric LONGITUDE (50.5 = 50

degrees 30 minutes) |

|

>A103 |

Numeric LATITUDE |

|

>A4 |

Name or Address Line 1 |

|

>A5 |

Address Line 2 |

|

>A6 |

Address Line 3 |

|

>A7 |

Postcode

(automatically converts to Grid Reference) |

|

>A8 |

Address Line 4 |

|

>A9 |

Address Line 5 |

|

>A11 |

Tag Field (up to 40 characters

may be used) |

|

>A12 |

Country (if used must be in a

column to the left of any postcode >A7 column to set the

relevant country) |

|

>A13 |

Special Delivery Instructions

Line 1 (80 characters text or up to 240 or all 3 lines) |

|

>A14 |

Special Delivery Instructions

SDI Line 2 (up to 80 characters text for line 2 only) |

|

>A15 |

Special Delivery Instructions

SDI Line 3 (up to 80 characters text for line 3 only) |

|

>A99 |

Pass Through Data for display

in user-defined columns |

|

>A17 |

Phone No. (or contact details)

– up to 24 characters of text may be entered. |

|

>A117 |

Pre Notification – value in

minutes |

|

>A217 |

Late or Post Notification –

value in minutes |

|

RESTRICTIONS Data

for Calls and Depots |

|

>R2 |

Opening Time - 1st Band |

|

>R3 |

Closing Time - 1st Band |

|

>R4 |

Opening Time - 2nd Band |

|

>R5 |

Closing Time - 2nd Band |

|

>R6 |

Day Restrictions |

|

>R8 |

Extra Time per Visit |

|

>R9 |

Work Difficulty Factor |

|

>R10 |

Pallet Fill Factor |

|

>R102 |

Booked Delivery Time in hhmm

format |

|

>R302 |

Booked Delivery Time Code in

text format (AM,PM etc.) |

|

>R106 |

Nominated Days |

|

>R107 |

Crew Size Required |

|

>R108 |

Delivery Priority |

|

>R203 |

Week No. of first Delivery |

|

>R7 |

Maximum Vehicle Class

(MUST BE LEFT JUSTIFIED TEXT) |

|

>R47 |

Banned Vehicle Class 1

(doesn’t remove other banned classes) |

|

>R57 |

Banned Vehicle Class 2

(doesn’t remove other banned classes) |

|

>R67 |

Banned Vehicle Class 3

(doesn’t remove other banned classes) |

|

>R77 |

Banned Vehicle Class 4

(doesn’t remove other banned classes) |

|

>R11 |

Explicit Vehicle Class |

|

>R37 |

Side Loading Restrictions (L = left, R = right, F = front, T = tail or

appropriate combinations , e.g. L ,RT,LF) |

| DEPOT Entity |

| >D1 |

Identifier (up to 10 characters

of text or numerics may be used) |

| >D0 |

New Depot Ident (changes the

existing ident to this new one, must follow in next

column to the right of >D1) |

| >A11 |

Tag Field |

| >D3 |

Maximum Daily Throughput of

PRODUCT 1 |

| >D4 |

Maximum Daily Throughput of

PRODUCT 2 |

| >D5 |

Maximum Daily Throughput of

PRODUCT 3 |

| >D6 |

Maximum Daily Throughput of

PRODUCT 4 |

| >D103 |

Maximum Daily Throughput of

PRODUCT 5 |

| >D104 |

Maximum Daily Throughput of

PRODUCT 6 |

| >D105 |

Maximum Daily Throughput of

PRODUCT 7 |

| >D106 |

Maximum Daily Throughput of

PRODUCT 8 |

| >D203 |

Maximum Daily Throughput of

PRODUCT 9 |

| >D204 |

Maximum Daily Throughput of

PRODUCT 10 |

| >D205 |

Maximum Daily Throughput of

PRODUCT 11 |

| >D206 |

Maximum Daily Throughput of

PRODUCT 12 |

|

Handling Costs & Product Costs (available to 5 decimal places) |

|

>D3H

Handling Cost for PRODUCT 1 |

>D3P Product Cost

of PRODUCT 1 |

|

>D4H

Handling Cost for PRODUCT 2 |

>D4P Product Cost

of PRODUCT 2 |

|

>D5H

Handling Cost for PRODUCT 3 |

>D5P Product Cost

of PRODUCT 3 |

|

>D6H

Handling Cost for PRODUCT 4 |

>D6P Product Cost

of PRODUCT 4 |

|

>D103H

Handling Cost for PRODUCT 5 |

>D103P Product

Cost of PRODUCT 5 |

|

>D104H

Handling Cost for PRODUCT 6 |

>D104P Product

Cost of PRODUCT 6 |

|

>D105H

Handling Cost for PRODUCT 7 |

>D105P Product

Cost of PRODUCT 7 |

|

>D106H

Handling Cost for PRODUCT 8 |

>D106P Product

Cost of PRODUCT 8 |

|

>D203H

Handling Cost for PRODUCT 9 |

>D203P Product

Cost of PRODUCT 9 |

|

>D204H

Handling Cost for PRODUCT 10 |

>D204P Product

Cost of PRODUCT 10 |

|

>D205H

Handling Cost for PRODUCT 11 |

>D205P Product

Cost of PRODUCT 11 |

|

>D206H

Handling Cost for PRODUCT 12 |

>D206P Product

Cost of PRODUCT 12 |

|

Loading Drivers from Spreadsheet |

|

>D1 |

Depot Name (must be the first column defined) |

|

>M1 |

Driver Identifier (Name) or Class Name (must be the

second column defined) |

|

>M2 |

No. Required (use 1 for an individual driver name) |

|

>M3 |

Can Drive up to Vehicle Category

(1-9 or 99)

99 = Mate (can’t drive a vehicle) |

|

>M4 |

Pay Scheme

(1-6) |

|

>M5 |

Start Depot Ident

(must already exist) |

|

>M105 |

Start Time

(default value applies to all days) |

|

>M205 |

Latest Start Time

(default value applies to all days) |

|

>M6 |

Finish Depot Ident

(must already exist) |

|

>M106 |

Finish Time

(default value applies to all days) |

|

>M7 |

Explicit Vehicle Id

(for individual drivers only) |

|

>M8 |

Explicit Trailer Id

(for individual drivers only) |

|

>M9 |

Explicit vehicle Class Wildcard |

|

>M10 |

Day Restrictions

(use 7 digit values with 0 and 3 for Sun-Sat) |

|

>M110 |

Night Out Banned

(Y for Yes or N for No) |

|

>M11 |

Driver Group

(1-4) |

|

>M12 |

Daily Limits – Maximum Shift Time |

|

>M13 |

Daily Limits – Maximum Overtime |

|

>M14 |

Daily Limits – Maximum Driving Time |

|

>M15 |

Daily Limits – Maximum Driving Distance |

|

>M16 |

Working Time Directive – Maximum No. of Days in DCP |

|

>M17 |

Working Time Directive – Maximum Shift Time in DCP |

|

>M18 |

Working Time Directive – Minimum Shift Time

remaining in DCP to start another day |

|

>M19 |

Working Time Directive – Maximum Cumulative Shift

over a number of Consecutive Days (see M20) |

|

>M20 |

Working Time Directive – No. of Consecutive Days for

Shift (see M19) |

|

>M118 |

Working Time Directive – Maximum Driving Time in DCP |

|

>M119 |

Working Time Directive – Maximum Cumulative Driving

Time over a number of Consecutive Days |

|

>M120 |

Working Time Directive – No. of Consecutive Days for

Driving (see M119) |

|

>M21 |

Driver Can Handle Products

(12 characters for the 12

products with Y or N ; e.g. YNYNYYYYYYYY) |

|

>M22 |

Driver Has Skills

(32 characters of text to represent the 32

possible skills with Y or N) |

|

>M116 |

Shift Pattern No. |

|

>M23 |

Explicit Mate No.1

(20 characters maximum)(drivers only) |

|

>M24 |

Explicit Mate No.2

(20 characters maximum)(drivers only) |

|

>M117 |

No of Lines in Shift Pattern |

|

>M216 |

Shift Pattern – Rota No. |

In addition to the default depots and times defined by >M5,

>M105, >M106, >M6 and >M106, different values for days of the

week may be input by adding an @”DAY” on the end of the column

header. Valid entries are @MON, @TUE, @WED, @THU, @FRI and @SAT.

Examples would include >M5@MON to change the Start Depot on a

Monday only, and >M106@WED to have a different Finish Time on

Wednesday

Loading

Vehicles from Spreadsheet

New field

types have been introduce to allow either vehicle class totals

or individual vehicle names (fleet nos. , registration nos. etc.)

to be loaded directly from an excel spreadsheet. Use the

>D1 depot identifier

as the first defined column and followed by the vehicle class

name preceded by

^> characters

(e.g. ^>ARTC ,

^>40FT or ^>R1). On each depot row individual names may be

entered by typing the required text (e.g. VU05 XXX or TR0050),

whilst class totals can be entered by using the required number

preceded by a # sign

(e.g. #20 for twenty, and #0 to set at zero or delete all

vehicles of this class at this depot).

|

|

>D1

|

^>ARTC

|

^>40FT

|

^>7.5T

|

^>7.5T

|

|

>>

|

DEP

|

ARTC1

|

40FT1

|

|

|

|

DEP

|

ARTC2

|

40FT2

|

|

|

|

DEP

|

|

|

|

#20

|

|

SAT

|

#0

|

40FTG2

|

7.5TG2

|

7.5TG21

|

|

>>

|

SAT

|

|

40FTG3

|

7.5TG3

|

7.5TG22

|

| Loading

Working Routes |

|

>W1 |

Relative Route Number |

|

>W2 |

Day Name (Sun,Mon,Tue,Wed,Thu,Fri,Sat) |

|

>W12 |

Week Number of Route (only if planning period is

more than 7days) |

|

>W3 |

Route Date (only if Daily Scheduling with Orders) |

|

>W4 |

Route Length in days |

|

>W14 |

Earliest Route Departure Time (in hhmm) |

|

>W24 |

Explicit Gate Departure Time for a Trip (in hhmm) |

|

>W5 |

Ident of Depot or Call |

|

>W15 |

Order or Shipment Ident (if Daily Scheduling) |

|

>W25 |

Quantity in Vehicle Unit1 (if Strategic) |

|

>D1 |

Owning Depot of Route |

|

>W6 |

Vehicle Ident |

|

>W7 |

Trailer Ident |

|

>W10 |

Driver’s Name |

|

>W8 |

Slot or Window Number for Call |

|

>W9 |

Product Group (1-12) in this slot (only required if

split by product or multiple) |

|

>W18 |

Call’s Profile Day No. (1-7 Sun-Sat) or

start day for a depot’s trip if defined on a depot line |

|

>W35 |

Call’s Profile Day Name (SUN, MON, TUE, WED, THU,

FRI, SAT) |

| Loading

Fixed routes |

|

>F1 |

Relative Route Number |

|

>F2 |

Day Name (Sun,Mon,Tue,Wed,Thu,Fri,Sat) |

|

>F22 |

Nominated Days (using 7digit 0111110 format) |

|

>F4 |

Route Length in days |

|

>F14 |

Departure Time (in hhmm) |

|

>F5 |

Ident of Depot or Call |

|

>F15 |

Dummy Shipment Ident (if Daily Scheduling) |

|

>D1 |

Owning Depot of Route |

|

>F6 |

Vehicle Ident |

|

>F7 |

Trailer Ident |

|

>F10 |

Driver’s Name |

|

>F8 |

Slot or Window Number for Call |

|

>F9 |

Product Group (1-12) in this slot (only required if

split by product or multiple) |

|

>F18 |

Call’s Profile Day No. (1-7 Sun-Sat) or

start day for a depot’s trip if defined on a depot line |

For more headers, detailed information and instructions please

see the DiPS user manual (pg.69)

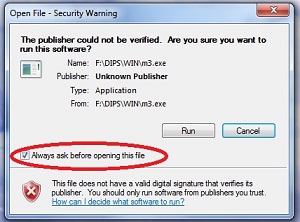

Stop Windows Security Warning

after downloading new version

After you have downloaded and copied the new version of M3 into

your DiPS/Win folder, you may find when you come to run DiPS you

will see a Windows Security Warning:

To stop it reappearing, untick the box next to "Always ask

before opening this file" then click Run. The next time you run

DiPS the warning will not show.

If your DiPS dongle needs to be returned to DiPS for repair, replacement, upgrade, etc.

Please send to:

DiPS

Bridge House

Bewdley

Worcestershire

DY12 1AB

*Please Note*:

You are required to send it

via Royal Mail Special Delivery or courier

to ensure it is signed for at both ends.