The Travel option is

used to produce a TTMATRIX which may be envisaged as a table of

times and distances between all the points in your study. All

the DiPS planning programs which rely on this detailed

information access the latest TTMATRIX and thus it must be

completed before any planning runs are attempted. Road Speeds

and other relevant values can be defined using the Travel ,

Parameters menu option which reveals the Matrix Properties

notebook.

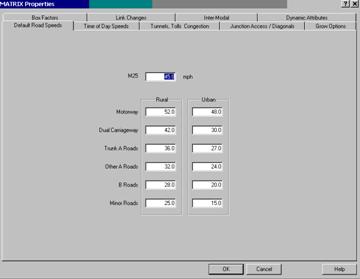

Default Road Speeds

Road databases are

stored in the roadfile, roadindx, and roadname files. For the UK these have a .UK file extension

and contain information on over 25,000 junctions and 75,000

links (down to street names, pedestrian areas, and one-way

systems for major urban areas). Each link has been allocated a

class based upon its type and where it is. There are two main

classes of rural or urban depending upon the location of the

link, but these may be additionally factored by use of Speed

Reduction Factors for specific cases such as congested urban

areas. The average road speed for each category of road may be

separately defined by the user. Any class of road or section of

road may be excluded by setting its speed to zero. The Default

settings have been developed over a number of years of

operational experience and have shown to produce industry

acceptable typical average speeds for HGVs. However speeds may

have to be modified for study data such as night running or the

use of smaller vehicles; and wherever companies have their own

agreed speed matrices.

To enable full

flexibility each class outlined below may be altered accordingly

:-

M25 - speed

class for all links of M25 motorway (all links are rural )

Other Motorways - all motorway

links apart from M25 (rural and urban)

Dual Carriageways - all road links

of more than 3 carriageways (whether or not a central

reservation is in place) for rural or urban areas

Trunk Roads - all Government

designated main trunk A roads (rural or urban)

Other A Roads - all other "A"

class roads (rural or urban)

B Roads - all roads with a "B"

classification (rural or urban)

Minor Roads - these have been

included where they constitute an important part of the

localised road network; for example in remote rural areas or in

urban areas (if they form an important access or recognised

through route)

The default road speeds are used to

define a standard set of speeds that apply to all vehicle

classes and at all times of the day or week.

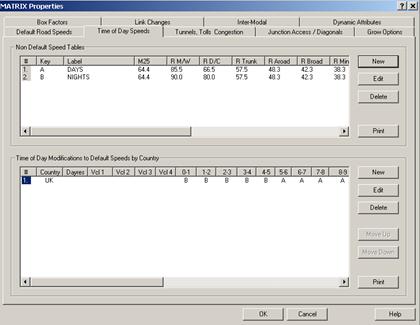

Time of Day Speeds

The Time of Day Road

Speeds option may be use to further refine road speeds to apply

different criteria

by time of day, day of week , country and vehicle class.

These parameters can

then reflect rush hours,

night running, or small non-HGV vehicle types for

example. Non Default Speed tables can be set and then applied to

days, vehicles and hours of the day.

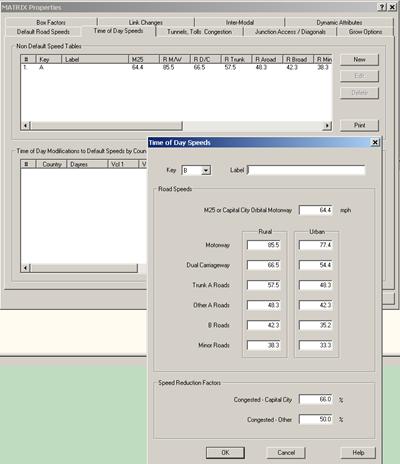

Non Default Speed Tables

To define Non Default

Speed tables, click on the New button to display the input

screen for a link, type the appropriate values into the fields

provided and then click on the OK button.

A key value (A-Z) is used to apply the speeds to the

Modification Tables and a description can also be entered for

the Table (e.g. Rush Hour, Small Vans).

Values may be entered for standard speeds and Congestion

factors. Certain links on the road database were nominated as

either congested, mountainous or narrow as the database was

being established or updated. It is possible using the

percentages available to factor any type of link (A road,

B road or minor road etc.) that has a defined attribute of this

sort. The values actually reduce the speeds by the indicated

amount and NOT to that level. As an example on an urban B road

(normal defined speed = 18mph) going into

Uk capital city -

Central London

(speed reduction factor of 66%), the actual factored speed along

the link would be reduced to 6 mph. To clear an existing table

click on the relevant # no. and click on Delete. To change an

existing table select it by clicking on the required No. in #

column and modify the values before clicking on the OK button.

Modification

Tables

To define Modification

tables, click on the New button to display the input screen for

a link, type the appropriate values into the fields provided and

then click on the OK button.

Set the required country fro the list available. A blank

Day Restrictions field would indicate that the table applies all

week, with a seven digit number representing Sun-Sat employed to

stop it being used on certain days. Use 3 to disable the table

on a day (e.g. 3000003 would mean that the table applies Mon-Fri

only). In the case

of vehicles if the table applies to all vehicle leave the fields

blank. To restrict use to certain vehicle types, use the list

box to add any class previously set up using the Vehicle Class

option. The Explicit Vehicle Class Wildcard field represents a

method of ensuring a set of particular vehicle classes

only are used. The ??

wildcards can be used to include a variety of vehicle types – as

an example Vehicle Wildcard =

??TN would include vehicle classes of 11TN , 17TN or

21TN.

A key value

(A-Z) is then used to apply the speeds set for that table to the

each hour of the day as necessary. To employ default speeds

simply leave the field blank.

To clear an

existing table click on the relevant # no. and click on Delete.

To change an existing table select it by clicking on the

required No. in # column and modify the values before clicking

on the OK button. To re-sequence a table in the list, simply

select it and then click on the Move Up or Move Down button.

Using the Speed Tables in DiPS

The

Speed and Modification Tables are employed automatically

wherever necessary within the DiPS system to match the criteria

set. In terms of

priority of use, the first

matching Modification Table in the list is applied; that

is should a particular vehicle class (e.g. 17TN) be entered into a

number of different modification tables, the speeds employed

will be the first that match the necessary day and time. Hence

the priority of use may be influenced by sequencing the tables

using the Move Up or Move Down buttons.

To display

the speed tables used for a route, use the Style Heading =

Matrix on Style, Route Headings or see the Itinerary output.

Tunnels,

Tolls, Congestion

The

road database of the UK is stored in the roadfile.uk,

roadindx.uk, and roadname.uk files and contains information on

over 25,000 junctions and 70,000 links (down to street names,

pedestrian areas, and one-way systems for major urban areas).

Each link has been allocated a class based upon its type; the

basis of which is covered by the Road Speeds parameters.

However for special

cases classes such as ferries, tunnels and toll roads have been

established. To control use of these links use the speeds

parameter - set the speed to 0 to effectively ban that road

class if necessary. Values may be input for the following types

:-

Motorway Tunnels, Other

Tunnels (Toll and Free), Ferries - UK only, Toll Roads - UK

only, Projected Motorways - previously in use for M40, but since

opening is now in more widespread use for all major road

construction currently being undertaken.

Certain

links on the road database were nominated as either congested,

mountainous or narrow as the database was being established or

updated. It is possible using the

percentages available to factor any type of link (A road,

B road or minor road etc.) that has a defined attribute of this

sort. The values actually reduce the speeds by the indicated

amount and NOT to that level. As an example on an urban B road

(normal defined speed = 18mph) going into

Central London (speed reduction factor of 66%), the

actual factored speed along the link would be reduced to 6 mph.

The default settings have been developed over a number of years

of operational experience and have shown to produce industry

acceptable typical average speeds for HGVs in congested areas.

Junction Access / Diagonals

The

Grid Reference Sensitivity value in the Junction Access /

Diagonals section of Travel parameters is used to reduce the

accuracy of time and distance calculations between calls that

are close together. Set at the default value of 1 meter, all

calls with separate grid references will have a time and

distance between them stored on the TTMATRIX produced by the Run

Matrix process. If however the value is set to one of the higher

levels, the matrix calculation will assume that all calls within

that square are essentially in the same place and therefore

don’t require a separate time and distance row to be stored.

This saves both disk space and reduces the time taken to run the

matrix process. The higher the value is, the more calls will be

considered to be in the same place. This feature may prove

helpful when large studies are being undertaken, where accuracy

in the time/distance between calls is less important. The

sensitivity will also apply in the process of adding Extra Time

and Distance to Diagonals of the Matrix, where calls have the

same grid reference. Values for this function are set in this

section also.

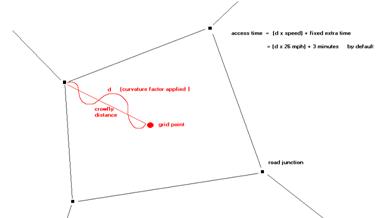

Junction Access

parameter is used by the Window process as each unique grid

reference is attached to between one and four road junctions

(depending upon local geography). The object of the analysis is

to provide all the data and work files required to calculate

travel time and distances in the Matgen process. In order to

access the nearest a crowfly calculation is done and calibrated

using the following parameters :-

1. Curvature Factor

- this is used as a multiplier on the straight line distance

calculated using the Pythagoras Theorem from the grid point to

the junction. It is designed to add extra weighting to this

distance as it is often found that the access is not a straight

line and may involve the use of a number of small access roads.

2. Crowfly Speed

- this average speed is used to calculate the travel time

between the two points using the distance value from (1).

3. Fixed Extra Time

- this value is added onto the junction access time (from (2))

of the grid point by MATRIX as it is calculating time between

points or by the ITINARY program as it calculating journey

times. This value can also compensate for the

otherwise zero

inter-drop travel time between point with the same grid

reference; a factor which is also covered by use of the Extra

Values to be Added to Diagonal Elements of the TTMATRIX

parameter.

The default parameters

have been arrived at with considerable experience and would not

normally require alteration.

Maximum Acceptable Distance from a Junction -

As part of the Window process of attaching all unique grid

reference point to the nearest junctions, a list may be obtained

of all call points more than a certain distance away from the

nearest junction. This is a way of identifying data that may

have been entered incorrectly into KINGPIN. By default the value

is set to 2 miles (or kms if used) for all new studies. Increase

or decrease the value accordingly if required. It is usual for

the output list generated by the MATRIX program to appear in the

file MATRIX.OUT. View or print this file to see the data.

The Extra Values to be

Added to Diagonal Elements of the TTMATRIX parameters may be

used in the MATRIX generation to add extra time and distance to

locations with the same grid reference. This will prove useful

if the basic data to be used is not as accurate as could be

hoped. For example the data may give five drop points with the

same basic address input with which to locate them of

Birmingham

and no postcode information, and the points may be scattered

throughout the area. By adding extra time and distance between

these drop points it becomes possible to make any route plans

more realistic. These values will be added to any Junction

Access time and

distance calculated, and will appear on route output prints as

normal inter-drop data. When using this facility values must be

kept to reasonable levels to avoid problems that may occur in

the routing process. If values are too high the algorithm will

consider a detour to a neighbouring drop to be a better option

than doing another on the same grid reference as the comparative

detour time to the former is less.

Grow Options

Travel optimisation in

the MATRIX generation is performed using the Cost Factors. Using

the default settings of 1.000 for cost per minute, and 0.001 for

cost per mile will optimise for time, and produce the shortest

time routes from one location to another as minimising time is

considered much more important than minimising distance. The

reverse will give shortest distance routes. Any combination of

values for time and distance may be used to govern optimisation

as required.

Matrix Build Control

parameters may be used in conjunction with the Matgen Required

Number of Destinations value to reduce the time taken to

complete a MATRIX run. The time the Matgen process takes to

calculate the information (often termed "build a row") is a

direct function of the first grow limit if the required number

of destinations is reached within that time, or the second grow

limit if the first was not sufficient. This second grow will

treble the time needed. By default the required number of

destinations is set to 9999, with the first grow limit at 240

minutes and the second at 480 minutes. Almost without exception

the value of 9999 exceeds the number of matrix rows, so the

program will always build to the second grow limit as the first

will always be unsuccessful. However if the required number of

destinations is reduced, set the first grow limit such that the

majority of rows calculated reach the required number in the

first grow, thus avoiding the second grow and extra time. It

should be remembered that for most studies the default matgen

parameters will be quite sufficient as their size does not

warrant any changes in this area. As a guide only if there are

more than 1,000 unique references should any action be

considered.

Matrix Required Number

of Destinations parameter defines the amount of TTMATRIX stored

by the system for the current model or study. The default value

of 9999

means build a full matrix, that is calculate time and

distance values for every unique grid reference to every other.

Whilst this is acceptable for an average size study, of say 300

calls, in the case of 5,000 unique grid locations, as each cell

of the matrix requires 6 bytes of space, the hard disk space

required to store the information would be 6 x 5000 x 5000

= 150 Mb

(which is more than the average machine can hold). To

reduce the requirement, a lower value for the number of

destinations would mean a much smaller file (saving disk space

and program running time for the planning packages). For example

if a figure of 200 were used in the case above the new size of

TTMATRIX would be 6 x 200 x 5000

= 6Mb , with

data now only being stored for the nearest 200 locations to each

unique grid reference.

In using the vehicle

scheduling programs it is unlikely in most studies that a route

point would be linked to another that is more than 200 away from

being the closest (given the number of call points necessary to

provide 5,000 unique grid locations). However it may be

necessary in some cases to provide more tolerance for certain

data.

The

MATRIX program will always store full rows of values from every

depot to every other grid reference in the window area, only the

inter-call times are affected by the destinations limit (the

TTMPART2 file). This means that the Print routines and Warefrom

module will work without any call to call data. Setting this

value to zero will also allow a matrix calculation to be done

using Postcode options. Therefore a fast matrix run for use with

these programs can be achieved by setting the Required Number of

Destinations field equal to ZERO before the matrix run. This

type of matrix will not be of any use for the route planning

programs as inter drop times would be required. This parameter

can also be used in conjunction with the Matgen Grow Limits

values to both reduce matrix size and run time. The time taken

to build a matrix is itself NOT a function of the required

number of destinations.

The

MATRIX program will always store full rows of values from every

depot to every other grid reference in the window area, only the

inter-call times are affected by the destinations limit (the

TTMPART2 file). This means that the Print routines and Warefrom

module will work without any call to call data. Setting this

value to zero will also allow a matrix calculation to be done

using Postcode options. Therefore a fast matrix run for use with

these programs can be achieved by setting the Required Number of

Destinations field equal to ZERO before the matrix run. This

type of matrix will not be of any use for the route planning

programs as inter drop times would be required. This parameter

can also be used in conjunction with the Matgen Grow Limits

values to both reduce matrix size and run time. The time taken

to build a matrix is itself NOT a function of the required

number of destinations.

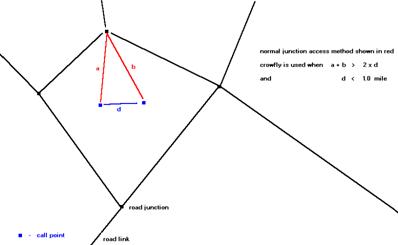

For call points that are

very close together geographically a crowfly calculation of

inter call time and distance information can be made rather than

the usual method of accessing the nearest road junction of the

network. This factor would be used in the routing operation.

Both the criteria set by

the ratio and distance must be satisfied before the system will

undertake such a process. By default the ratio setting is 2.00

and the distance is 1.0 mile; that is the distance taken

to access the nearest junction and return to the second

location must be twice the crowfly distance between the two

points, and this crowfly distance separating the two points must

be less than one mile.

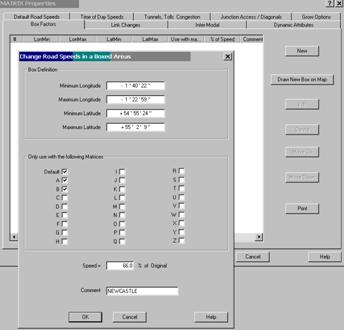

Box

Factors

All road speeds in a

boxed area can be increased or decreased using the Speed Factors

facility. A factor of 120% will have the effect of increasing

all road speeds by 20%; factors less than 100% will have a

negating effect.

Box areas may be

established using mouse or Latitude and Longitude. Where two

boxes overlap the largest box number value will apply (i.e.

box

2 further down the list has priority over box 1).

Any areas not defined by

a boxed grid will use the default settings for road speeds. The

boxed area factor will have priority over default road settings

but not over any changes made to specific links using the

Individual Road Link Changes facility. A text description may

also be applied to each boxed area established using the field

provided.

Box Factors may be

applied to each Speed Table defined (Default and A-Z), allowing

further control on speeds in the defined area by time of day or

day of the week. Simply place a tick by each speed table

required.

To add box areas using the mouse to draw a rectangle , first draw a

pop-up window around the area in question on the graphics panel

using the LHB. Then after selecting Travel Parameters, Box

Factors, click on the Draw New Box on Map button.

To create a new Speed Box, click on the New

button to display the input screen for a box, type the

appropriate values into the fields provided and then click on

the OK button. To clear any existing values click on the

relevant # no. and click on Delete. To change an existing box

select it by clicking on the required No. in # column and modify

the values before clicking on the OK button. To move a Box,

simply select it and then click on the Move Up or Move Down

button. To send a copy of the settings to the default printer

use the Print button.

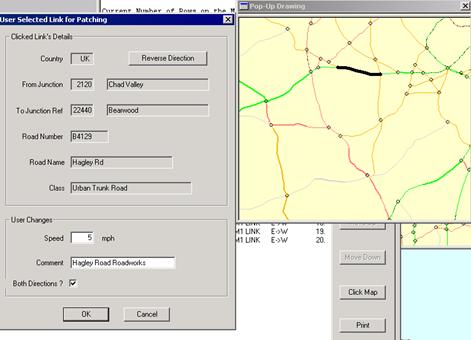

Link Changes

It is possible to

restrict the speed on any particular road section on the

roadfile database by using the Individual Road Link Changes to

modify the relevant base value set in either Road Speeds,

Special Classes of Road, or Road Speed Factors by Boxed Area

parameters. This facility is intended to cope with everyday

problems such as long-term roadworks, traffic queues, or toll

road links.

Modify

Link Changes using Graphics Screen

Modify

Link Changes using Graphics Screen

To add link changes

using the Highway Mode graphics screen to highlight links, first

draw a pop-up window around the area in question using the LHB.

Then after selecting Travel Parameters, Link Changes, click on

the New - Click Map button. The graphics window will then

re-draw displaying junction circles. To select a link, click on

the link required using the LHB and the dialog box will appear

as indicated. The dialog will display the link including

junction points and road information. Input the Changes as

required (set the speed = 0 to disable the link) and set the

both directions indicator. Click Ok to save changes or Cancel to choose another

link from the map if the current selection is not correct.

To clear any existing

values click on the relevant # no. and click on Delete. To

change an existing link select it by clicking on the required

No. in # column and modify the values before clicking on the OK

button. To move a link in the list, simply select it and then

click on the Move Up or Move Down button. To send a copy of the

settings to the default printer use the Print button.

Certain links will

appear in this section for every new study as part of the set-up

phase. These links include the Humber, Severn, Tamar and

Forth bridges and the Dartford Tunnel/Bridge. Speeds

for these will be set by default at 20 mph, and will over-ride

any constraints set in any of the sections discussed above.

It is useful to note

that any restriction place between two junctions will only apply

in that direction. For the restriction to be effective in both

directions two lines must be set up - one with the

A -> B

direction and the other with the

B -> A

direction.

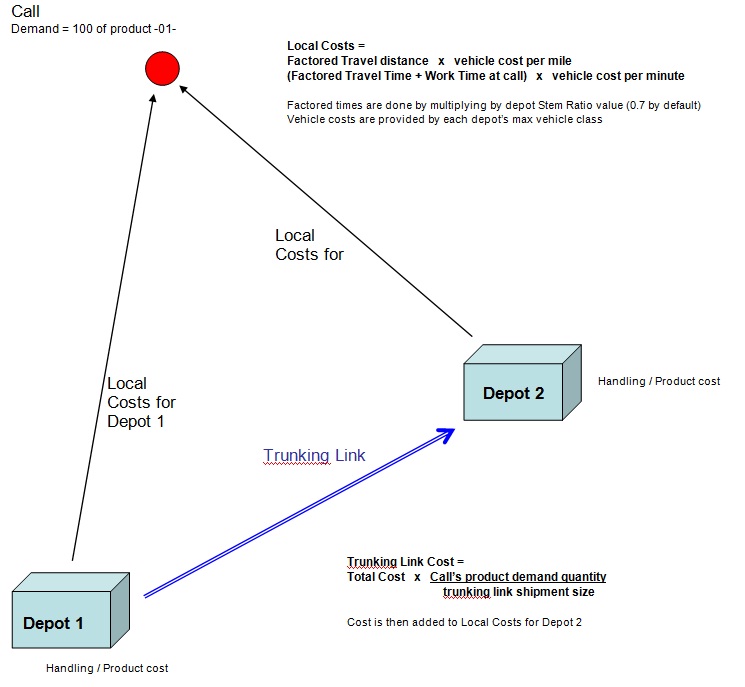

Running the WAREFROM

program will allocate calls to depots based upon a minimum costs

calculation. An

indication of the cost calculation is shown in the following

diagram. Key cost information must be set up before attempting

to run the routine. Minimum criteria are vehicle costs (either

cost per min, cost per mile, or both), so that Local Cost

calculations may be done.

Other more detailed

costs may be input into the model as required, using either

trunking links or product/handling costs at each depot. All

costs setup in the model are summed to produce an overall cost

per call, which is then divided by the total vehicle unit1 at

each call to provide a final cost per unit figure used to

allocate the call to its cheapest depot.

The Warefrom COST

screen may be regarded as the most important to check before

using Warefrom, as this screen defines the method and costs to

be used by the program in calculating Total Costs and in

performing any reallocation of calls between depot areas or

supply chains. The Maximum Number of Choices field must have a

valid number before the program is run (for normal studies 3

should suffice). The depot screen does contain two other items

of data used by Warefrom - the Stem Ratio and Stem Time fields.

The Depot Stem Ratio is applied to the times/distances for the

depot in question which are produced by Warefrom, giving results

which are closer to the more detailed Vanguard runs. Indeed, the

Stem Ratio may be obtain by running Vanguard, where it is given

as the ratio of total distance driven by all Vanguard routes to

the total of stem distances for all calls.

It is important to

remember that a depot with a Stem Ratio which is lower than that

of another depot will be at an advantage (other things being

equal) and will therefore be preferred in the allocation of

areas. For example, where a call is equidistant from the two

depots, say 100 miles, the depot with a ratio of 0.6 will be

preferred to the other with a ratio of 0.7. The relative costs

(at 1p per mile) would be 60p and 70p. The main function of the

Stem Ratio is to take inter-drop travel into account within

Warefrom - the program otherwise produces results based solely

on Stem time/distance.

In its simplest form

the Local Costs are summed –

Local Costs =

Factored Travel distance x

vehicle cost per mile

+

(Factored Travel Time +

Work Time at call)

x vehicle cost

per minute

Factored times are done by multiplying by depot Stem Ratio value

(0.7 by default)

Vehicle costs are provided by each depot’s max vehicle class

When

Trunking Links and Handling / Product costs are added, the

following items are also summed as a trunking cost and then

added into the total cost –

Trunking

Link Cost

Total Cost

x

Call’s product demand quantity

Trunking link shipment size

Handling

Costs

+

Handling Cost at depot x

product

demand quantity

Product Costs

+

Product Cost at depot x

product

demand quantity

An

in-depth listing of the calculated costs for calls and supply

chain numbers may be obtained by setting the Detailed Call Costs

Report. These more detailed cost reports may be achieved for ALL

calls (by default = ALL) or a single call ident number, input in

the field provided. The format gives a section for each call

location with a separate line for each delivery depot and supply

chain loaded into the run, so that comparative costs may be

examined. The ident with address information is provided along

with the vehicle class providing the cost information. This

vehicle type is obtained from the Maximum Vehicle field of the

Call, being the largest vehicle that may access the call. If any

particular vehicle type is not available at a delivery depot,

this supply chain option will not be considered for the call and

a warning message will be displayed accordingly. The TOTAL COST

calculation is the sum of all the constituent parts in use and

the call is allocated initially to the cheapest supply chain

option.

Calls that are outside

of the Depot Stem Time limit will not have calculated costs and

will be marked with a TOO FAR AWAY or REQUIRED ROUTE LENGTH >

MAX message. Any Carriage Paid calls allocate to the nearest

cheapest depot (the appropriate Stem Driving times from each

delivery depot location are displayed) with the Vehicle Class

set to 3rd to nominate a third party distribution function.

Explicitly allocated calls are marked with an

e and costs

not calculated from all supply chains since that call cannot be

considered for re-allocation.

Calls

that do not meet any valid depot criteria are marked with a

DEFERRED - NO DEPOT CHOICES warning message, as in the example

below with no possible vehicle choices to meet access

restrictions. Cost per Unit (Vehicle Unit 1) are calculated to

show the relative cost differences from each chain taking into

account the product demand volumes. It is this figure that is

compared if the call requires allocation to its second or third

choice supply chain with the first choices being over-allocated.

2)

Costs From Each Supply Chain

Supply

TOTAL Trunk

----- Local Costs ----------

Ident Name

Depot Chain

COST

Cost

Veh

Fixed Time

Dist

C102

LEEDS

A 1

43

0

7.5T

0

41

2 Cost/Unit=

21.50000

B

2

58

27

7.5T

0

25

6 Cost/Unit=

29.00000

C

3

75

21

7.5T

0

40

14 Cost/Unit=

37.50000

D

4

613

510

7T-4

0

80

23 Cost/Unit=

306.50000

Other

Parameters in Warefrom

The

Depot Stem Time limits the extent to which depot areas may be

grown. Calls which are further than this limit from the depot in

question cannot be allocated to that depot's area. A common use

of this parameter is to ensure that areas can be served by

specific one-day or two-day routes. By limiting the area to the

equivalent of half of a shift's driving time, calls would not be

allocated where deliveries would require a second day out. The

possible service levels for specific calls can be investigated

in Vanguard/Egotrip. Any vehicle class or class wildcard

specified in a Call Banned Vehicle parameter will also prevent

that call being allocated to a distribution Depot with that

class (or matching for wildcards) set as its Maximum Vehicle.

For example a call with a banned vehicle of

A??? would

not be allocate to a depot with a maximum set to AR22 or ARIG.

If a call cannot be allocated to a depot for this reason the

message

BANNED VEHICLE CLASS (Wrong Type of Supplier)

will appear in the Detailed Call Costs output section.